Navigating Supply Chain Disruptions: Expert Strategies for US Businesses

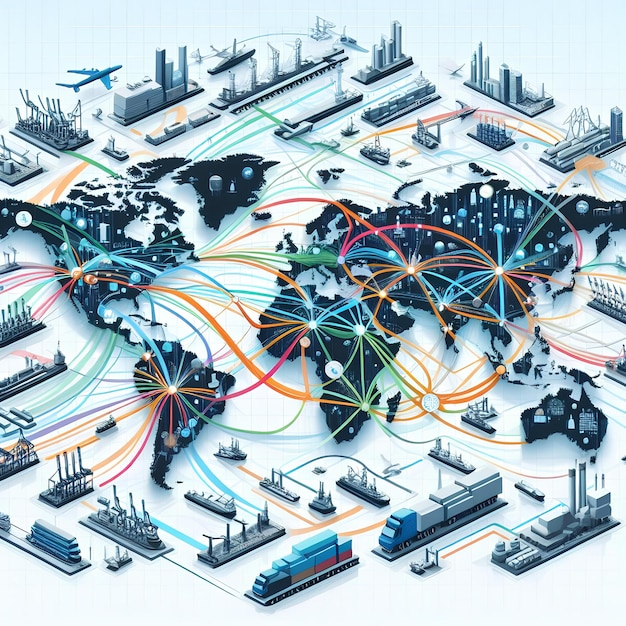

Supply Chain Disruptions: Expert Strategies for US Businesses to Mitigate Risks in the Next 6 Months involves bolstering resilience through diversified sourcing, enhanced risk assessment, technological integration, and proactive communication to navigate and minimize potential impacts.

Are you prepared for the next wave of supply chain disruptions: expert strategies for US businesses to mitigate risks in the next 6 months? Unforeseen events can cripple even the most robust businesses, but with the right insights and strategies, you can safeguard your operations and maintain a competitive edge.

Understanding the Evolving Landscape of Supply Chain Disruptions

The global supply chain has become increasingly complex and interconnected, making it vulnerable to various disruptions. Understanding the current landscape and the factors contributing to these disruptions is crucial for developing effective mitigation strategies. Let’s delve into the key aspects of this evolving landscape.

Factors Contributing to Supply Chain Vulnerabilities

Several factors have amplified the vulnerabilities within global supply chains, leading to increased disruptions. These include geopolitical instability, natural disasters, and technological challenges. Each factor presents unique risks that businesses must proactively address.

The Impact of Geopolitical Instability

Geopolitical tensions, trade wars, and political instability in key regions can significantly disrupt supply chains. These events can lead to tariffs, sanctions, and border closures, affecting the flow of goods and materials. Staying informed about global political dynamics is essential for mitigating these risks.

- Mitigate geopolitical risks by diversifying sourcing locations.

- Monitor political developments and adjust supply chain strategies accordingly.

- Develop contingency plans for alternative sourcing and transportation routes.

Assessing the Impact of Climate Change and Natural Disasters

Climate change and the increasing frequency of natural disasters pose a significant threat to supply chains. Floods, hurricanes, and droughts can disrupt production, transportation, and distribution networks. Resilience planning is key to minimizing the impact of these events.

Understanding the potential effects of these disruptions, it’s evident that being proactive is essential. Businesses need to start by assessing their current supply chain to pinpoint any areas of vulnerability.

Conducting a Thorough Risk Assessment

Before implementing any mitigation strategies, it’s crucial to conduct a thorough risk assessment of your supply chain. A comprehensive assessment will help identify potential vulnerabilities and prioritize mitigation efforts. Here’s how to approach this critical task.

Identifying Key Vulnerabilities in Your Supply Chain

Start by mapping your entire supply chain, from raw materials to final delivery. Identify critical points and potential bottlenecks where disruptions could have the most significant impact. Consider factors such as single-source suppliers, geographical concentration, and reliance on specific transportation routes.

Analyzing Potential Disruption Scenarios

Once you have identified key vulnerabilities, analyze potential disruption scenarios that could affect your supply chain. Consider a range of events, including natural disasters, cyberattacks, and supplier bankruptcies. Evaluate the likelihood and potential impact of each scenario to prioritize your mitigation efforts.

- Use scenario planning to identify a range of potential disruptions.

- Evaluate the likelihood and impact of each scenario.

- Prioritize mitigation efforts based on risk severity.

Utilizing Data Analytics for Risk Management

Data analytics can play a crucial role in risk management by providing insights into supply chain performance and potential disruptions. By analyzing historical data, real-time information, and predictive models, businesses can identify patterns, trends, and anomalies that may indicate impending risks.

With a clear understanding of potential risks, the next step involves establishing robust plans for managing them effectively. Next, we define some plans to reduce risk.

Developing Robust Contingency Plans

Contingency plans are essential for mitigating the impact of supply chain disruptions. These plans outline the steps to be taken in response to various disruption scenarios, ensuring business continuity. Let’s explore the key elements of developing effective contingency plans.

Diversifying Your Sourcing and Supplier Base

One of the most effective strategies for mitigating supply chain risks is to diversify your sourcing and supplier base. Relying on a single supplier or region can leave your business vulnerable to disruptions. By spreading your sourcing across multiple suppliers and locations, you can reduce your dependence on any one source.

Establishing Alternative Transportation Routes

Transportation bottlenecks can significantly disrupt supply chains, especially during times of crisis. Establishing alternative transportation routes can help maintain the flow of goods and materials even when primary routes are unavailable. Consider options such as rail, air, and inland waterways.

Building Inventory Buffers and Safety Stocks

Maintaining adequate inventory buffers and safety stocks can provide a cushion against supply chain disruptions. By holding extra inventory, you can continue to meet customer demand even when supplies are delayed or interrupted. Determine the appropriate level of inventory based on your lead times, demand variability, and risk tolerance.

Having robust risk management strategies in place can also reduce your risk on suppliers or logistics partners.

Leveraging Technology for Supply Chain Resilience

Technology plays a pivotal role in enhancing supply chain resilience. Advanced technology solutions can provide real-time visibility, improve decision-making, and automate key processes. Here are some ways to leverage technology for greater resilience.

Implementing Real-Time Visibility and Tracking Systems

Real-time visibility and tracking systems (RTTV) provide end-to-end visibility into your supply chain, allowing you to monitor the location and status of goods and materials in real-time. This visibility enables you to quickly identify and respond to potential disruptions, minimizing their impact.

Utilizing AI and Machine Learning for Predictive Analytics

Artificial intelligence (AI) and machine learning (ML) can be used to analyze vast amounts of data and predict potential supply chain disruptions. These technologies can identify patterns and trends that may be invisible to human analysts, enabling businesses to proactively mitigate risks. Predictive analytics can help you anticipate demand fluctuations, identify potential supplier issues, and optimize inventory levels.

- Implement AI-powered tools to forecast disruptions.

- Utilize machine learning to optimize inventory levels.

- Leverage predictive analytics to improve decision-making.

Adopting Blockchain Technology for Enhanced Transparency

Blockchain technology can enhance supply chain transparency by providing a secure and immutable record of transactions. This transparency can help build trust among supply chain partners and improve traceability, making it easier to identify and resolve issues. Blockchain can also streamline processes such as customs clearance and payment processing.

Building a resilient supply chain also means having financial flexibility to manage and respond to unexpected challenges.

Securing Financial Flexibility and Insurance Coverage

Financial flexibility and adequate insurance coverage are essential components of a resilient supply chain. Having access to funds and insurance policies can help businesses weather disruptions and minimize financial losses. Let’s explore how to secure these vital resources.

Establishing Lines of Credit and Emergency Funds

Establishing lines of credit and emergency funds can provide businesses with access to cash when needed. These resources can be used to cover unexpected expenses, such as increased transportation costs, inventory shortages, or supplier bankruptcies. Work with your bank or financial institution to establish these resources.

Investing in Supply Chain Insurance

Supply chain insurance can protect businesses against financial losses resulting from disruptions. These policies can cover a range of risks, including property damage, business interruption, and cargo losses. Consult with an insurance provider to determine the appropriate coverage for your business.

With financial stability secured, it’s crucial to communicate effectively with all stakeholders involved in the supply chain.

Enhancing Communication and Collaboration

Effective communication and collaboration are critical for managing supply chain disruptions. Clear and timely communication among partners can help minimize confusion, coordinate responses, and maintain trust. Here’s how to improve communication and collaboration within your supply chain.

Establishing Clear Communication Channels

Establish clear communication channels with all supply chain partners, including suppliers, distributors, and customers. Use a variety of communication methods, such as email, phone, and video conferencing, to ensure that information is transmitted quickly and accurately. Designate points of contact for each partner to streamline communication.

Conducting Regular Stakeholder Meetings

Conduct regular meetings with key stakeholders to discuss supply chain performance, potential risks, and mitigation strategies. These meetings provide an opportunity to share information, coordinate efforts, and build relationships. Involve representatives from all key functions, such as procurement, logistics, and sales.

- Schedule regular stakeholder meetings.

- Share performance data and risk assessments.

- Involve representatives from all key functions.

Implementing Collaborative Planning and Forecasting

Collaborative planning and forecasting can improve supply chain visibility and coordination. Share demand forecasts, inventory levels, and production schedules with key partners. Use collaborative planning tools to align plans and resolve discrepancies. This collaboration can help reduce inventory costs, improve customer service, and minimize disruptions.

In conclusion, communication is key so everyone can prepare for any unexpected situation.

| Key Point | Brief Description |

|---|---|

| 🌍 Diversify Sourcing | Reduce reliance on single suppliers or regions. |

| 📊 Risk Assessment | Identify and analyze potential disruptions. |

| 🛡️ Contingency Plans | Develop strategies for various disruption scenarios. |

| 📢 Communication | Enhance collaboration across the supply chain. |

Frequently Asked Questions (FAQ)

▼

The primary causes include natural disasters, geopolitical instability, supplier failures, and unexpected surges in demand.

▼

Businesses can assess vulnerabilities by mapping their supply chain, identifying critical points, and analyzing potential disruption scenarios.

▼

Technology enhances resilience through real-time visibility, predictive analytics, and blockchain for transparency.

▼

Communication helps minimize confusion, coordinate responses, and maintain trust among supply chain partners during disruptions.

▼

Companies can secure financial flexibility by establishing lines of credit, emergency funds, and investing in supply chain insurance.

Conclusion

In conclusion, navigating supply chain disruptions: expert strategies for US businesses to mitigate risks in the next 6 months requires a proactive and multifaceted approach. By implementing these strategies, businesses can build more resilient supply chains, minimize the impact of disruptions, and maintain a competitive edge in an increasingly volatile global landscape.