Robotics in US Manufacturing: A 5-Year Forecast for Growth

The Future of Robotics in US Manufacturing: A 5-Year Forecast anticipates significant growth driven by automation needs, technological advancements, and reshoring initiatives, revolutionizing production processes and workforce dynamics.

Are you prepared for the robotic revolution in US manufacturing? Our in-depth The Future of Robotics in US Manufacturing: A 5-Year Forecast explores the key trends, challenges, and opportunities shaping the industry’s automation journey, offering valuable insights for businesses and professionals navigating this transformative era.

Robotics Revolution: Transforming US Manufacturing

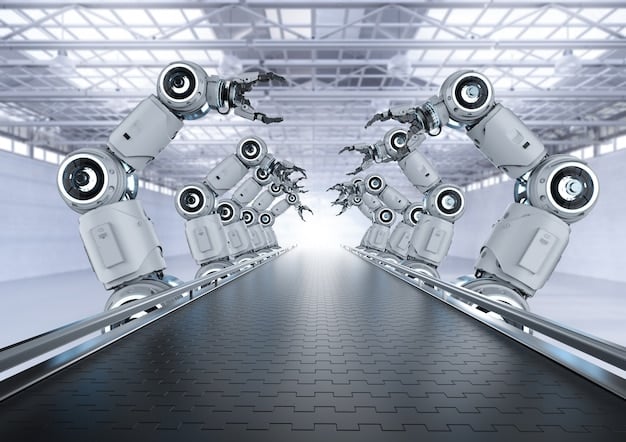

The manufacturing sector in the United States is on the cusp of a technological leap, largely driven by the integration of robotics. These advanced machines are no longer just a futuristic concept; they are swiftly becoming integral components of modern production lines, impacting efficiency, precision, and overall output.

As manufacturers seek to enhance their competitiveness and adapt to evolving market demands, the adoption of robotics is accelerating. This transformation promises to reshape the industry landscape, introducing new possibilities and challenges that businesses must navigate to thrive in the coming years.

Key Drivers of Robotics Adoption

Several factors are fueling the increased use of robotics within US manufacturing:

- Increased Efficiency: Robots can operate continuously without fatigue, leading to higher production rates and reduced downtime.

- Enhanced Precision: Automated systems ensure consistent quality and minimize errors, resulting in fewer defects and improved product reliability.

- Labor Shortages: Robotics help address labor shortages by automating repetitive or dangerous tasks, freeing up human workers for more skilled roles.

These drivers are pushing manufacturers to invest in robotics, seeking a competitive edge in an increasingly demanding global market. The results are streamlined operations, reduced costs, and more resilient supply chains.

Ultimately, the shift towards robotics represents a fundamental change in the way goods are produced, promising a future where technology and human expertise work hand-in-hand to drive innovation and economic growth in the US manufacturing sector.

The 5-Year Forecast: Growth and Trends

Forecasting the future of any industry is complex, but the trends pointing towards continued growth of robotics in US manufacturing are compelling. Over the next five years, several key developments are expected to shape the sector, offering both opportunities and potential challenges for stakeholders.

From advancements in artificial intelligence to shifts in global supply chains, understanding these trends is crucial for manufacturers looking to stay ahead of the competition and capitalize on the benefits of automation.

AI and Machine Learning Integration

One of the most significant trends is the increasing integration of AI and machine learning into robotic systems. This allows robots to:

- Adapt to Changes: AI-powered robots can learn from their environment and adjust their actions in real-time, making them more flexible and responsive.

- Predictive Maintenance: Machine learning algorithms can analyze data from sensors to predict when maintenance is needed, reducing downtime and improving efficiency.

- Improved Collaboration: AI enables robots to work more effectively alongside human workers, enhancing safety and productivity.

The convergence of AI and robotics offers immense potential for transforming manufacturing processes, driving greater efficiency and innovation.

These developments highlight the growing importance of data analytics and the need for manufacturers to invest in the infrastructure and skills required to leverage these technologies effectively.

Impact on the US Workforce

The increasing adoption of robotics in manufacturing raises important questions about its impact on the US workforce. While automation has the potential to displace some workers, it also creates new opportunities and transforms existing roles.

Understanding these dynamics and preparing for the changes ahead is crucial for ensuring a smooth transition and maximizing the benefits of robotics for both businesses and workers.

Creating New Opportunities

Robotics creates new jobs in areas such as:

- Robot Design and Manufacturing: The growing demand for robots creates opportunities for engineers, technicians, and manufacturers specializing in automation technologies.

- Robot Programming and Maintenance: Skilled workers are needed to program, maintain, and repair robotic systems.

- Data Analysis: Analyzing data generated by robots requires professionals with expertise in statistics, machine learning, and data visualization.

By investing in training and education, the US can ensure that its workforce is prepared to take advantage of these new opportunities.

Ultimately, the successful integration of robotics into the workforce requires a proactive approach to retraining, education, and workforce development. By focusing on these areas, the US can ensure that its workers are equipped to thrive in the new world of automated manufacturing.

Challenges and Obstacles to Widespread Adoption

Despite the immense potential of robotics in manufacturing, several challenges and obstacles may hinder its widespread adoption. Addressing these issues is crucial for unlocking the full benefits of automation and ensuring a smooth transition for businesses and workers.

These challenges range from high initial investment costs to concerns about cybersecurity and the need for specialized training. Overcoming these hurdles requires a concerted effort from both the public and private sectors.

High Initial Investment Costs

The upfront costs of purchasing and implementing robotic systems can be significant, particularly for small and medium-sized enterprises (SMEs). These costs include:

- Equipment: The price of robots varies depending on their capabilities but can be substantial.

- Integration: Integrating robots into existing production lines requires specialized expertise and can be complex and expensive.

- Training: Workers need training to operate, maintain, and program robotic systems.

To overcome this barrier, governments and industry organizations can offer incentives and support to help SMEs invest in robotics.

By addressing these challenges, the US can create a more favorable environment for robotics adoption, unlocking its full potential to transform the manufacturing sector and drive economic growth.

The Role of Government and Industry Initiatives

Government and industry initiatives play a crucial role in shaping the future of robotics in US manufacturing. By providing funding, setting standards, and fostering collaboration, these initiatives can accelerate the adoption of robotics and ensure that its benefits are shared widely.

Support and guidance can help manufacturers overcome challenges, develop new technologies, and prepare the workforce for the changes ahead.

Incentivizing Innovation

Government initiatives can incentivize innovation in robotics through:

- Research Funding: Investing in research and development of new robotic technologies.

- Tax Credits: Offering tax credits for companies that invest in robotics.

- Grants and Subsidies: Providing grants and subsidies to support the adoption of robotics, particularly for SMEs.

These measures can stimulate innovation, drive down costs, and make robotics more accessible to a wider range of manufacturers.

Ultimately, the success of these initiatives depends on strong collaboration between government, industry, and academia, as well as a shared commitment to fostering innovation and ensuring that the benefits of robotics are shared widely across the US economy.

Future Innovations and Disruptive Technologies

The coming years are expected to bring a range of future innovations and disruptive technologies that will further transform the landscape of robotics in US manufacturing. These advancements promise to push the boundaries of automation, enabling new capabilities and efficiencies.

Staying abreast of these developments is crucial for manufacturers seeking to maintain a competitive edge and capitalize on the opportunities presented by the next wave of technological innovation.

Advanced Sensors and Vision Systems

Improvements in sensors and vision systems will enable robots to:

- Better Object Recognition: Robots will be able to identify and manipulate objects with greater precision and accuracy.

- Safer Collaboration: Advanced sensors will allow robots to work more safely alongside human workers.

- Real-Time Monitoring: Robots will be able to monitor their own performance and identify potential problems before they lead to downtime.

These advancements will make robots more versatile, adaptable, and capable of performing a wider range of tasks.

As these and other innovations continue to emerge, it is crucial for manufacturers to stay informed and proactive, embracing the potential of disruptive technologies to transform their operations and drive future growth.

| Key Point | Brief Description |

|---|---|

| 🤖 Automation Growth | Significant growth expected in US manufacturing due to increased automation needs. |

| ⚙️ Key Drivers | Efficiency, precision, and labor shortages are driving robotics adoption. |

| 🧑🏭 Workforce Impact | Creates new jobs, but retraining and education are crucial for workforce adaptation. |

| 🚀 Future Innovations | Advanced sensors, AI, and collaborative robots will further transform manufacturing. |

Frequently Asked Questions

The primary driver is the need for increased efficiency and precision in manufacturing processes to maintain a competitive edge in the global market.

Robotics will create new jobs in areas such as robot design, programming, and maintenance, but retraining is essential for workers to adapt to these roles.

High initial investment costs and the need for specialized training are significant challenges, especially for small and medium-sized enterprises.

Government and industry initiatives can incentivize adoption by providing funding, setting standards, and fostering collaboration between businesses and researchers.

Expect advancements in areas like AI-powered robots, advanced sensors, and improved collaboration between humans and robots on the factory floor.

Conclusion

As we look toward the future, it is clear that robotics will play an increasingly important role in US manufacturing. By addressing the challenges and embracing the opportunities, and with an eye on The Future of Robotics in US Manufacturing: A 5-Year Forecast, the US can harness the transformative power of robotics to create a more competitive, innovative, and prosperous manufacturing sector for all.