Latest Robotics & Automation Innovations Transforming US Manufacturing

The latest innovations in robotics and automation for US manufacturing include collaborative robots, AI-powered systems, digital twins, and advanced sensors, enhancing efficiency, safety, and customization capabilities.

The manufacturing sector in the U.S. is undergoing a significant transformation, driven by cutting-edge advancements in what are the latest innovations in robotics and automation for US manufacturing?. These innovations promise to revolutionize production processes, enhance efficiency, and boost overall competitiveness in the global market.

The Rise of Collaborative Robots (Cobots) in Manufacturing

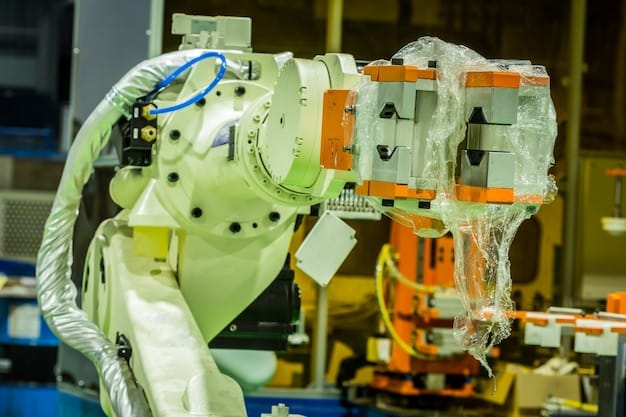

Collaborative robots, or cobots, are designed to work alongside human workers, enhancing productivity and safety. Unlike traditional industrial robots that require safety cages, cobots are equipped with sensors and safety features that allow them to operate in close proximity to humans.

This adaptability makes them ideal for a wide range of tasks, from assembly and packaging to quality inspection and machine tending. Cobots are also easier to program and redeploy, offering greater flexibility for manufacturers looking to adapt to changing market demands.

Benefits of Cobots

Cobots offer several key advantages that make them an attractive investment for manufacturers:

- Enhanced Safety: Built-in sensors and force-limiting technology prevent collisions and injuries.

- Increased Productivity: Cobots can handle repetitive or physically demanding tasks, freeing up human workers for more skilled work.

- Improved Flexibility: Easy programming and redeployment allow manufacturers to quickly adapt to new tasks and product designs.

- Reduced Costs: Cobots can operate 24/7, reducing labor costs and increasing production output.

The integration of cobots in US manufacturing is not just about replacing human labor; it’s about creating a synergistic environment where humans and robots work together to achieve greater efficiency and productivity. Companies that embrace this collaborative approach are better positioned to thrive in the evolving manufacturing landscape.

Artificial Intelligence (AI) Integration in Robotic Systems

Artificial intelligence is revolutionizing robotics and automation in manufacturing. AI-powered robots are capable of learning from data, adapting to changing conditions, and making decisions independently, leading to increased efficiency and reduced downtime.

AI algorithms can analyze vast amounts of data from sensors, cameras, and other sources to optimize production processes, predict equipment failures, and improve product quality. This level of intelligence enables manufacturers to create more responsive and resilient supply chains.

AI Applications in Manufacturing

AI is being applied in various areas of manufacturing, including:

- Predictive Maintenance: AI algorithms analyze sensor data to predict when equipment is likely to fail, allowing manufacturers to schedule maintenance proactively and avoid costly downtime.

- Quality Control: AI-powered vision systems can detect defects in products with greater accuracy and speed than human inspectors.

- Process Optimization: AI algorithms analyze production data to identify bottlenecks and optimize processes for maximum efficiency.

- Supply Chain Management: AI can forecast demand, optimize inventory levels, and improve logistics, leading to more responsive and resilient supply chains.

The integration of AI in robotic systems is transforming manufacturing from a reactive to a proactive discipline. By leveraging the power of AI, manufacturers can anticipate problems, optimize processes, and improve product quality, ultimately gaining a competitive edge in the market.

Digital Twins: Virtualizing the Manufacturing Process

Digital twins are virtual replicas of physical manufacturing assets, processes, and systems. These virtual models allow manufacturers to simulate and optimize their operations in a virtual environment, reducing the risk of costly errors and improving overall efficiency.

By creating a digital twin of a manufacturing plant, companies can test new processes, optimize equipment performance, and train employees in a safe and cost-effective environment. Digital twins also enable manufacturers to monitor the performance of their assets in real-time, identify potential problems, and make data-driven decisions to improve operations.

How Digital Twins Enhance Manufacturing

Digital twins offer several key benefits that make them a valuable tool for manufacturers:

- Process Optimization: Simulate and optimize production processes in a virtual environment before implementing them in the real world.

- Equipment Monitoring: Monitor the performance of equipment in real-time and identify potential problems before they lead to downtime.

- Training and Simulation: Train employees in a safe and cost-effective virtual environment.

- Predictive Maintenance: Use data from the digital twin to predict when equipment is likely to fail and schedule maintenance proactively.

Digital twins are transforming manufacturing by providing a virtual sandbox where companies can experiment, innovate, and optimize their operations without disrupting the physical production process. This technology is empowering manufacturers to make smarter decisions, reduce costs, and improve overall performance.

Advanced Sensors and IoT Integration

Advanced sensors and the Internet of Things (IoT) are playing an increasingly important role in manufacturing automation. Sensors collect data from equipment, processes, and the environment, while IoT platforms enable manufacturers to connect these sensors to the internet and analyze the data in real-time.

This connectivity allows manufacturers to monitor the performance of their assets, track production progress, and identify potential problems remotely. IoT platforms also enable manufacturers to integrate data from multiple sources, creating a holistic view of their operations and enabling data-driven decision-making.

Benefits of IoT in Manufacturing

The integration of IoT in manufacturing offers numerous advantages:

- Real-time Monitoring: Monitor the performance of equipment, processes, and the environment in real-time.

- Remote Control: Control equipment and processes remotely.

- Data-Driven Decision-Making: Integrate data from multiple sources to create a holistic view of operations and enable data-driven decision-making.

- Predictive Maintenance: Use sensor data to predict when equipment is likely to fail and schedule maintenance proactively.

By leveraging advanced sensors and IoT platforms, manufacturers can gain greater visibility into their operations, improve efficiency, and reduce downtime. This technology is empowering manufacturers to create more connected, responsive, and resilient production systems.

3D Printing and Additive Manufacturing

3D printing, also known as additive manufacturing, is transforming the way products are designed and manufactured. This technology enables manufacturers to create complex parts and products directly from digital designs, without the need for traditional tooling or machining processes.

3D printing is particularly well-suited for producing customized or low-volume parts, as well as creating prototypes and tooling. The technology is also being used to manufacture end-use parts in a variety of industries, including aerospace, automotive, and medical.

Advantages of 3D Printing

3D printing offers several advantages over traditional manufacturing methods:

- Design Flexibility: Create complex parts and products that would be difficult or impossible to manufacture using traditional methods.

- Customization: Produce customized parts and products tailored to individual customer needs.

- Rapid Prototyping: Create prototypes quickly and cost-effectively.

- Reduced Waste: Minimize material waste compared to traditional machining processes.

3D printing is revolutionizing manufacturing by enabling companies to create innovative products, reduce lead times, and lower costs. This technology is empowering manufacturers to compete more effectively in the global market and create new opportunities for growth and innovation.

The Impact of 5G on Robotics and Automation

The rollout of 5G networks is expected to have a significant impact on robotics and automation in manufacturing. 5G offers faster speeds, lower latency, and greater bandwidth compared to previous generations of wireless technology, enabling new applications and capabilities for robots and automated systems.

With 5G, robots can communicate with each other and with central control systems in real-time, enabling more coordinated and efficient operations. 5G also enables manufacturers to deploy robots in remote or hazardous environments, where wired connections are not feasible.

How 5G Enhances Robotics and Automation

5G technology enables several advancements in robotics and automation:

- Real-time Communication: Robots can communicate with each other and with central control systems in real-time, enabling more coordinated and efficient operations.

- Remote Deployment: Deploy robots in remote or hazardous environments, where wired connections are not feasible.

- Enhanced Data Analysis: Process large amounts of data generated by robots and sensors in real-time, enabling more sophisticated control and optimization.

- Improved Security: Protect robots and automated systems from cyber threats with enhanced security features.

5G is poised to accelerate the adoption of robotics and automation in manufacturing by providing a more reliable, secure, and high-performance communication infrastructure. This technology will enable manufacturers to create more connected, intelligent, and efficient production systems.

| Key Point | Brief Description |

|---|---|

| 🤖 Cobots | Collaborative robots working alongside humans for enhanced productivity and safety. |

| 🧠 AI Integration | AI-powered robots learning from data, optimizing processes, and predicting equipment failures. |

| 🌐 Digital Twins | Virtual replicas of manufacturing assets for simulation, optimization, and training. |

| 📡 IoT & Sensors | Advanced sensors and IoT platforms enabling real-time monitoring and data-driven decision-making. |

FAQ

Cobots enhance safety, increase productivity by handling repetitive tasks, improve flexibility with easy redeployment, and reduce labor costs through 24/7 operation.

AI algorithms analyze sensor data to predict equipment failures, allowing proactive scheduling of maintenance to avoid costly downtime and extend equipment lifespan.

A digital twin is a virtual replica of physical assets, enabling manufacturers to simulate processes, optimize equipment, and train employees in a virtual environment.

IoT integration provides real-time monitoring, remote control capabilities, data-driven decision-making, and predictive maintenance through sensor data analysis and connectivity.

5G enhances real-time communication, allows remote deployment, improves data analysis, and enhances security, enabling more coordinated and efficient robotic operations.

Conclusion

The integration of these latest innovations in robotics and automation is reshaping US manufacturing, enhancing efficiency, safety, and customization. Embracing these advancements will enable manufacturers to remain competitive in the evolving global market.